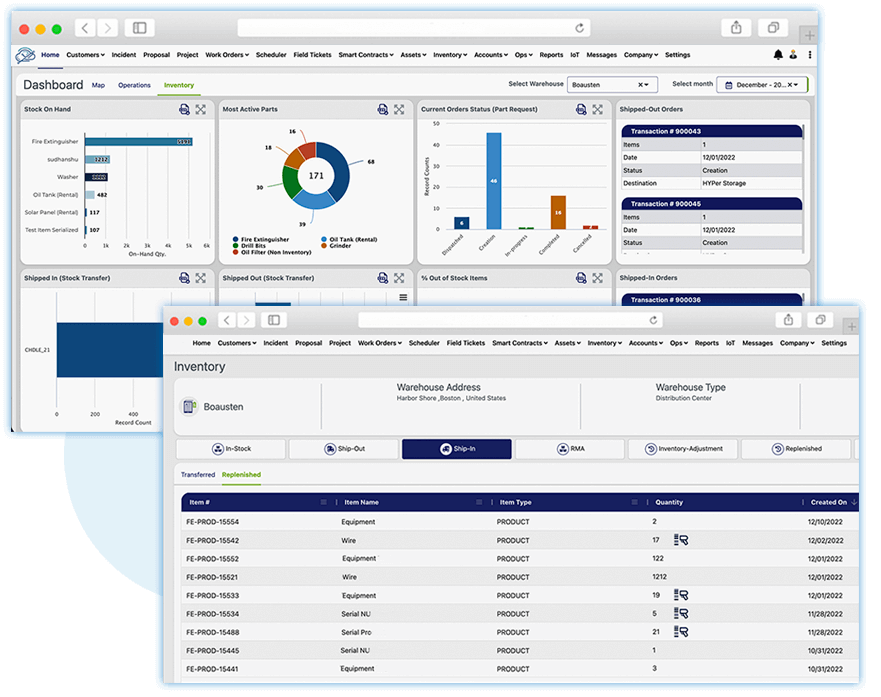

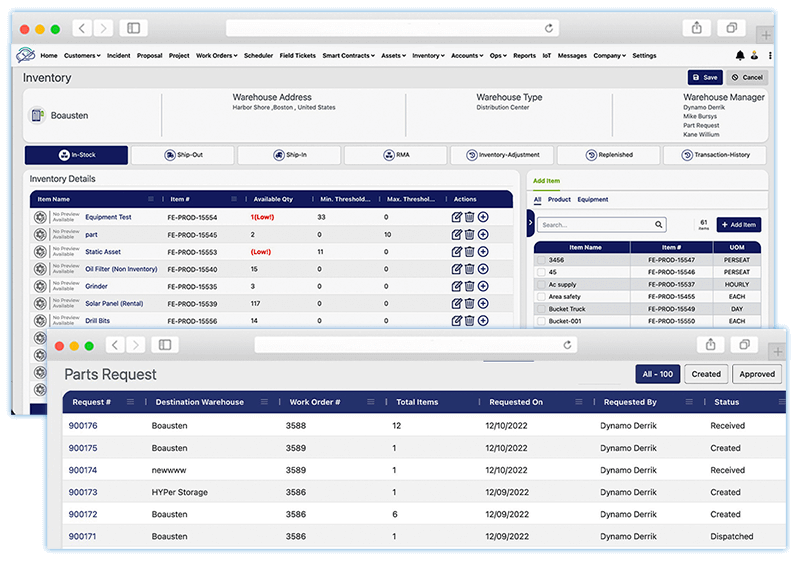

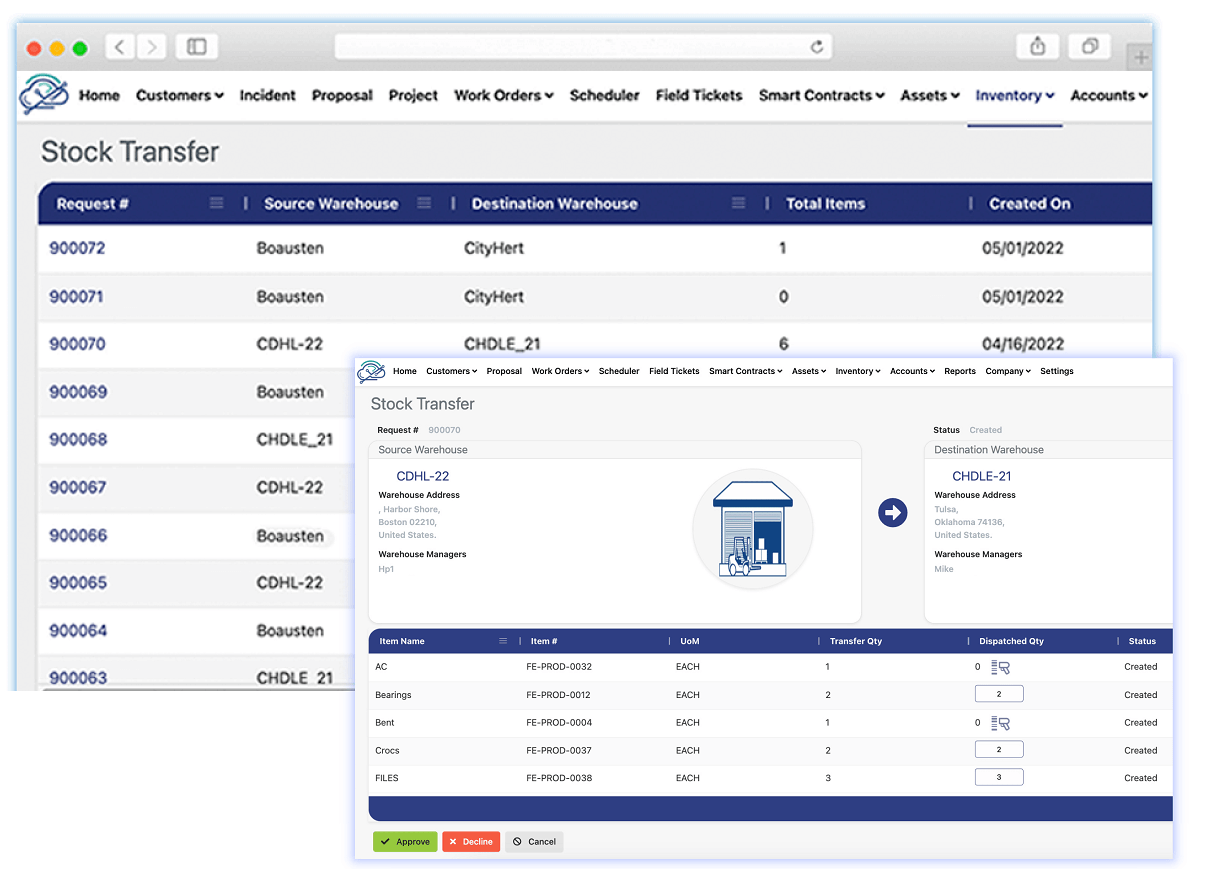

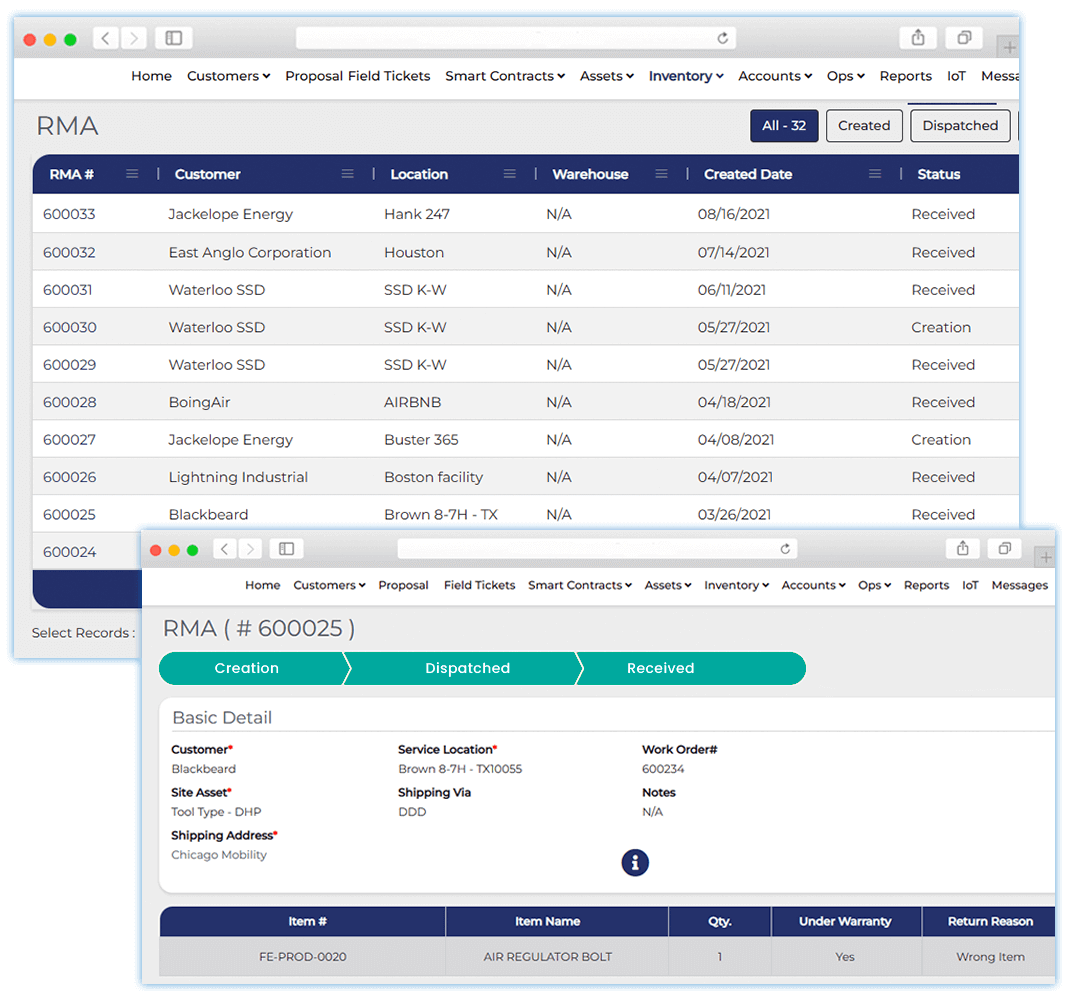

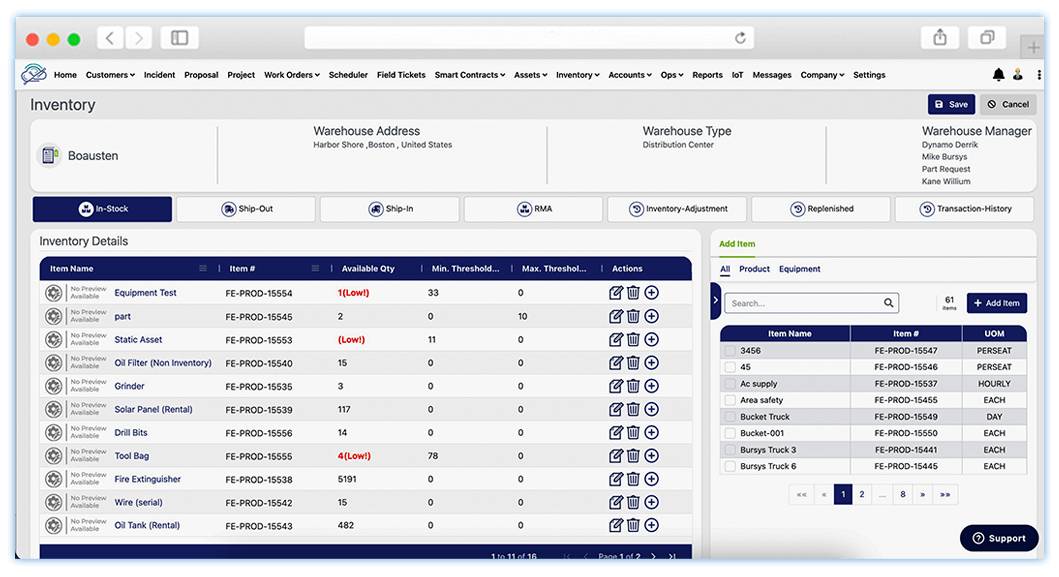

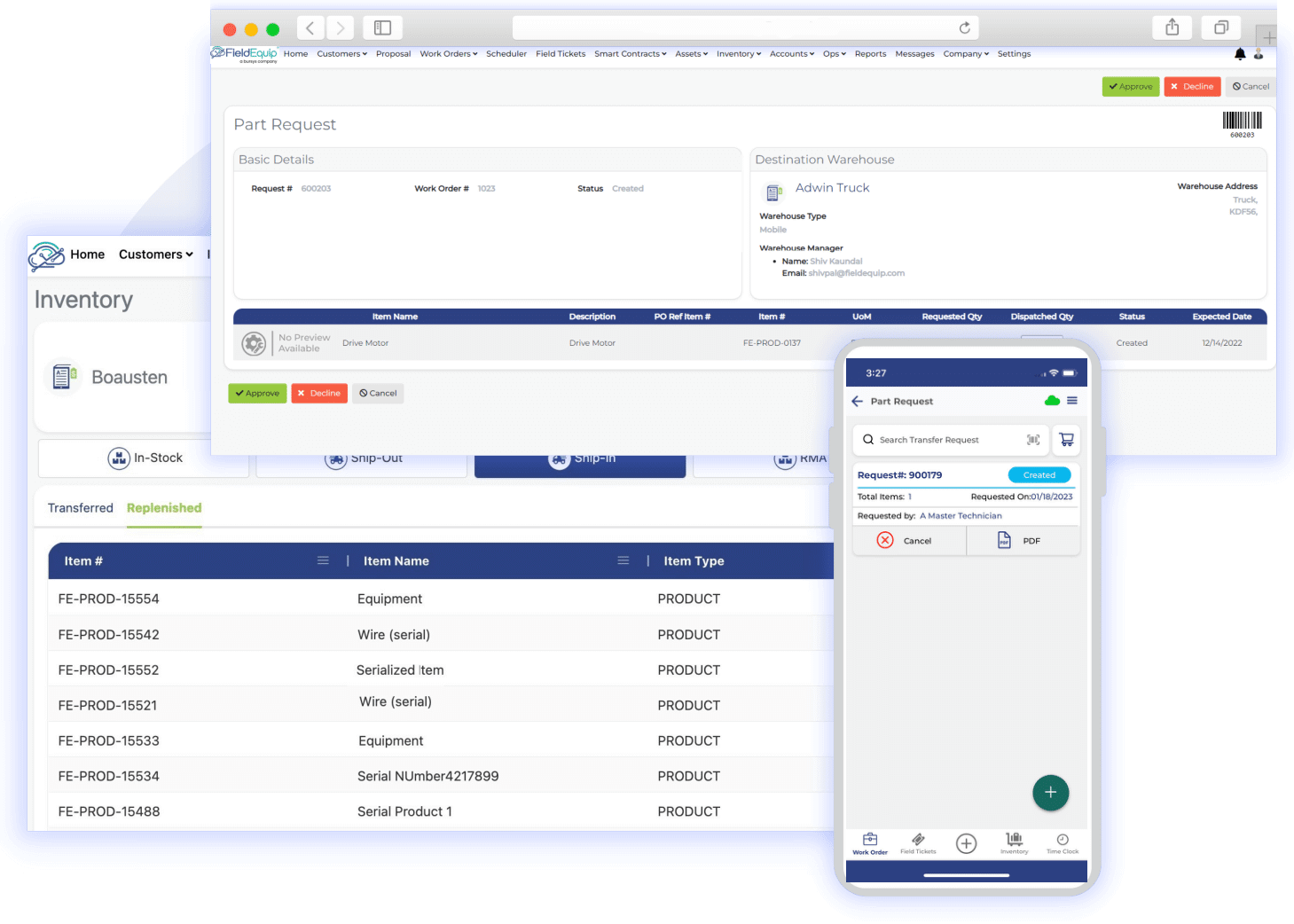

Easily Find the Exact Part Required and Save Time with Field Service Inventory Management Software

Locating the nearest spare part is no longer a hassle! FieldEquip’s mobile inventory tracking system saves time by helping find the correct location of every part. In addition, to maintain optimum efficiency, FieldEquip’s mobile inventory management solution also sends automatic notifications when inventory reaches a specific threshold level. As a result, organization and field operations experience fewer workflow disruptions and increased efficiency.